Prototyping

Precision manufacturing CNC services

CNC Machining

CNC Turning

Industrial casting for prototype design

Vacuum Casting

Die Casting

Prototype sheet metal fabrication

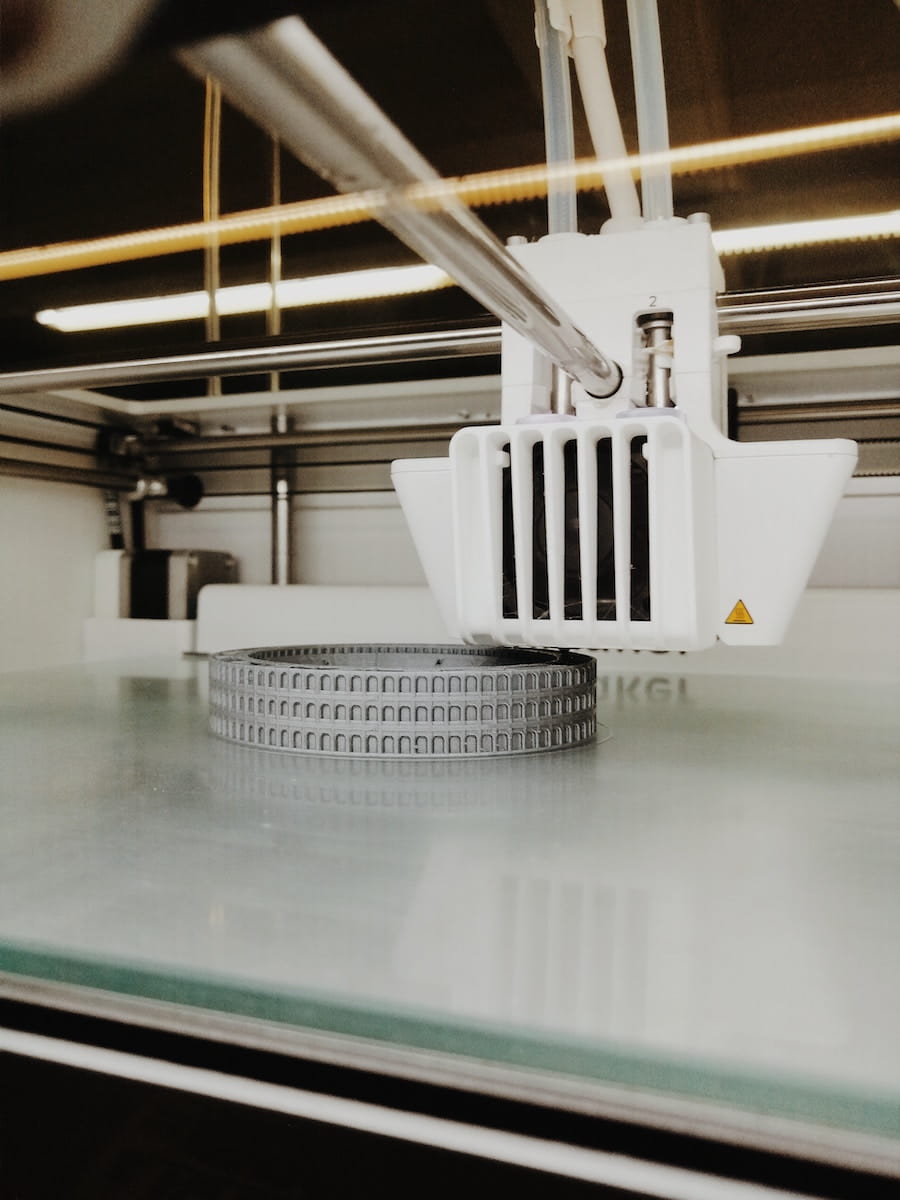

Industrial rapid prototyping with 3d printing

Plastic prototype injection molding manufacturing

Industrial low volume production prototyping

Industrial aluminum extrusion for prototype manufacturing

Industrial vacuum for plastic prototype manufacturing

Industrial reaction injection molding for prototype

A prototype is considered a graphic representation to scale and concrete of a part or all of a product, part or object on an idea that is intended to realize in real scale; therefore, having a prototype will allow you to understand in a visual way, evaluate the object, anticipate possible failures or errors and validate whether it is worth making the investment for the fulfillment of its functionality. In Engtechnik we have different prototyping options to apply the most optimal in your project.

Looking for an automation solution for your company?

Contact us today for a free consultation or more information